The Science of Powder Coating Oven Heat Transfer

Powder coating is a popular method for providing a durable and attractive finish to various products, from automotive parts to household appliances. Central to this process is the powder coating oven, a critical component that ensures the powder coating cures correctly and uniformly. The science behind heat transfer in these ovens is complex but essential to understand for anyone involved in powder coating. This blog delves into the intricate workings of heat transfer within a powder coating oven, exploring how different factors influence the final result.

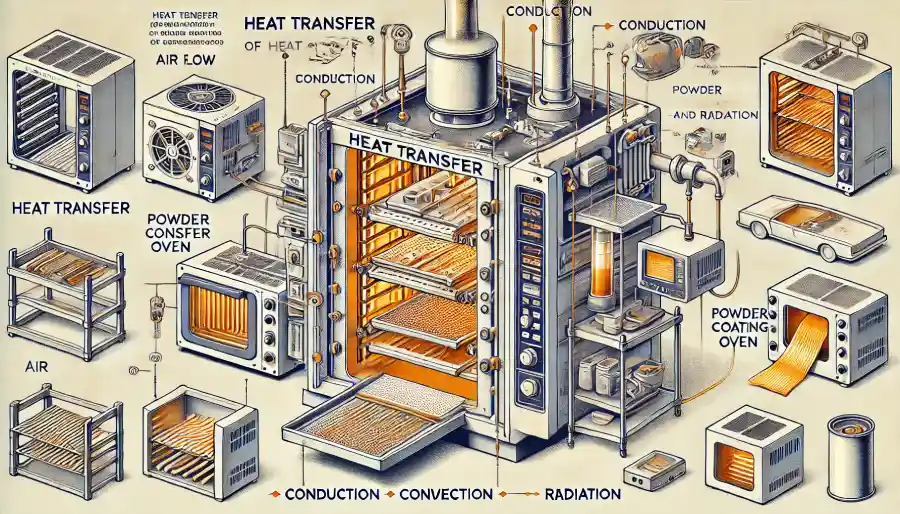

How Heat Moves Through the Powder Coating Oven

Understanding how heat moves through a powder coating oven is key to mastering the coating process. Heat transfer in these ovens occurs through a combination of conduction, convection, and radiation. Each of these modes plays a crucial role in ensuring that the coating cures evenly across the surface of the product.

In a modern powder coating oven, conduction occurs as heat moves through the oven walls and into the air. This heat then transfers to the coated object, starting from the outermost layer and gradually moving inward. The process requires precise control to avoid overheating the exterior while ensuring the interior is adequately cured. This balance is what makes heat transfer in a powder coating oven a carefully controlled process that requires expertise and precision.

The Role of Convection in Even Coating

Convection is one of the primary methods of heat transfer in a powder coating oven. It involves the movement of heat through the circulation of air within the oven. In an industrial powder coating oven, convection ensures that the heated air reaches all parts of the coated object, promoting an even cure.

The effectiveness of convection in a powder coating oven depends on the airflow patterns within the oven. Properly designed ovens will have controlled airflow that circulates heat uniformly, reducing the risk of hot spots or uneven coating. This is especially important in large-scale industrial powder coating ovens, where consistent quality is critical. The role of convection in these ovens cannot be overstated, as it directly impacts the final appearance and durability of the coating.

Understanding Radiant Heat in Powder Coating Ovens

Radiant heat is another significant factor in the heat transfer process within powder coating ovens. Unlike convection, which relies on air movement, radiant heat is transferred directly from the heat source to the coated object without needing a medium like air or water. This form of heat transfer is particularly useful for curing coatings on objects with complex shapes or intricate details.

In a modern powder coating oven, radiant heat allows for more precise control over the curing process. It ensures that even the most challenging areas of the coated object receive the necessary amount of heat for proper curing. The use of radiant heat in powder coating ovens is especially advantageous in applications where uniformity and precision are paramount.

The Impact of Airflow on Heat Distribution

Airflow within a powder coating oven plays a crucial role in distributing heat evenly. Without proper airflow, some areas of the coated object may receive too much heat, while others may not receive enough. This uneven heat distribution can lead to an inconsistent coating, with some parts being overcured and others undercured.

In industrial powder coating ovens, engineers carefully design the airflow system to optimize heat distribution. This includes positioning fans and vents strategically to ensure that hot air circulates evenly throughout the oven. The goal is to create a uniform temperature profile within the oven, allowing for consistent curing across the entire coated object. Proper airflow is essential for achieving the high-quality finish that powder coating is known for.

How Oven Design Affects Heat Transfer Efficiency

The design of a powder coating oven has a significant impact on heat transfer efficiency. Factors such as the size of the oven, the materials used in its construction, and the placement of heat sources all influence how effectively heat is transferred to the coated object. A well-designed oven will maximize heat transfer while minimizing energy consumption, leading to more efficient and cost-effective operation.

In modern powder coating ovens, attention to detail in design can make a substantial difference in performance. For example, using materials with high thermal conductivity can improve the efficiency of heat transfer, while strategically placing heating elements can ensure even distribution of heat. These design considerations are critical for producing consistent, high-quality coatings and achieving optimal curing times. In an industrial setting, where productivity and quality are paramount, the design of the powder coating oven can be the difference between success and failure.